Papia, a housewife of Bahiman village at Ullapara of Sirajganj, has set an example of how one can become self-reliant by supplying beef, processed in a safe way, to the market. She recently sold a cow for Tk3.8 lakh that she had bought at Tk30,000 two and a half years ago. She still has over 30 similar improved-breed cows in her farm. Her journey began seven years ago, when her husband Shaheen, having incurred losses in his grocery business, began raising two bulls they had at home.

A training in livestock farming, business management, and cattle rearing from the Department of Youth Development proved a boon for her, leading her to becoming a successful entrepreneur in safe meat.

According to the district livestock office, there are 6.25 lakh cattle available for sacrifice this year in Sirajganj, with a market value of approximately Tk2,500 crore. This is expected to yield farmers a profit of at least Tk500 crore.

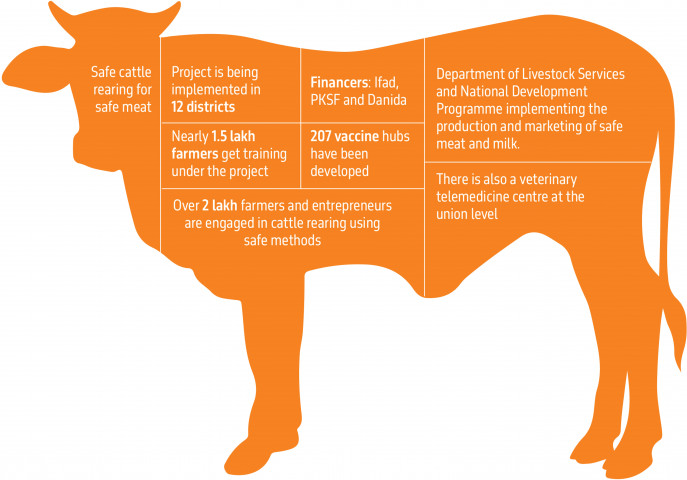

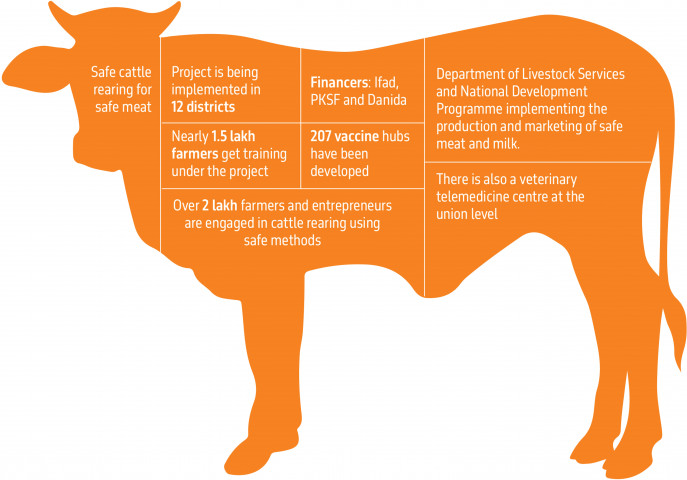

With financial support from the International Fund for Agricultural Development, Palli Karma-Sahayak Foundation (PKSF), and Danish International Development Agency along with the Department of Livestock Services in Sirajganj, non-governmental development organisation National Development Programme (NDP) is implementing the production and marketing of safe meat and milk under Rural Microenterprise Transformation Project (RMTP).

According to information from the organisation, 28,000 farmers in Pabna and Sirajganj have been trained in safe beef production methods. In these farms, 1.02 lakh cattle have been raised using safe practices.

Project being implemented in 12 districts

Under the project in 12 districts across the country, including Bogura, Thakurgaon, and Bhola, 2 lakh 1 thousand 480 farmers and entrepreneurs are engaged in cattle rearing funded by foreign investments, using safe methods.

Nomita Halder, managing director of PKSF, told TBS that the project is playing a role in expanding businesses and increasing the income of nearly three lakh poor people involved in the livestock sector.

“Safe meat and dairy products produced under the project are already making their mark in domestic and international markets. Successful entrepreneurs are contributing to the national economy by exporting their products (such as meat pickles and cheese) abroad,” she said.

Farmers say that they are currently receiving much more technical, technological, and marketing support than before. They are being introduced to modern veterinary care, which is making the production of safe meat easier, they say.

According to officials, 1,577 livestock service providers have trained 1,41,546 farmers all over the country under the project. In addition to safely raising cattle, the livestock service providers are also utilising cow dung to produce organic fertiliser. Sirajganj is one of the prominent districts involved in the initiative.

Safe beef sales centre draws attention

Mama-Bhagne Agro Safe Meat, a safe beef sales centre, at Shialkol in Sirajganj sadar, has achieved ISO certification. It has gained recognition in the district as well. Even the district livestock officers regularly purchase beef from there. It sells meat at market prices. There is a separate clean and hygienic area for slaughtering cattle there. After halal slaughter, the blood and waste of the cattle are buried under the ground.

Abul Kalam Azad, owner of the meat firm, said since its launch in February, beef from an average of 45 cows is being sold every month in the establishment.

Alauddin Khan, executive director of NDP, said, “Due to safe practices, Bengal Meat has already purchased 2,382 cows from the area. The beef is being supplied to Shwapno outlets as well. We are working to create successful entrepreneurs with various forms of financial assistance, market preparation, and training. And indirectly, thousands of people have found employment opportunities through cattle farming.”

Sirajganj district livestock officer Md Omar Faruque said modern methods have been adopted while establishing the meat sales centre at Shialkol.

“I myself have visited there. Before the cattle are slaughtered, it has its own quarantine arrangements. A veterinarian examines the cattle to see if they are healthy before slaughtering. Healthy cattle are slaughtered using scientific methods. This ensures the nutritional value of the beef remains intact. Overall, it can be said to be safe meat,” he said.

Faruque also said, “We are now working to popularise the method so that more youth get encouraged in the field. Training arrangements are being made for farmers. They are also playing a significant role in controlling animal diseases, especially through vaccination programmes. Safe meat production is increasing. There is also a growing demand in the market. New entrepreneurs are emerging.”

https://www.tbsnews.net/agriculture/modern-cattle-farming-generates-safe-meat-demand-rise-878416