Drip irrigation system expansion in horticulture sector

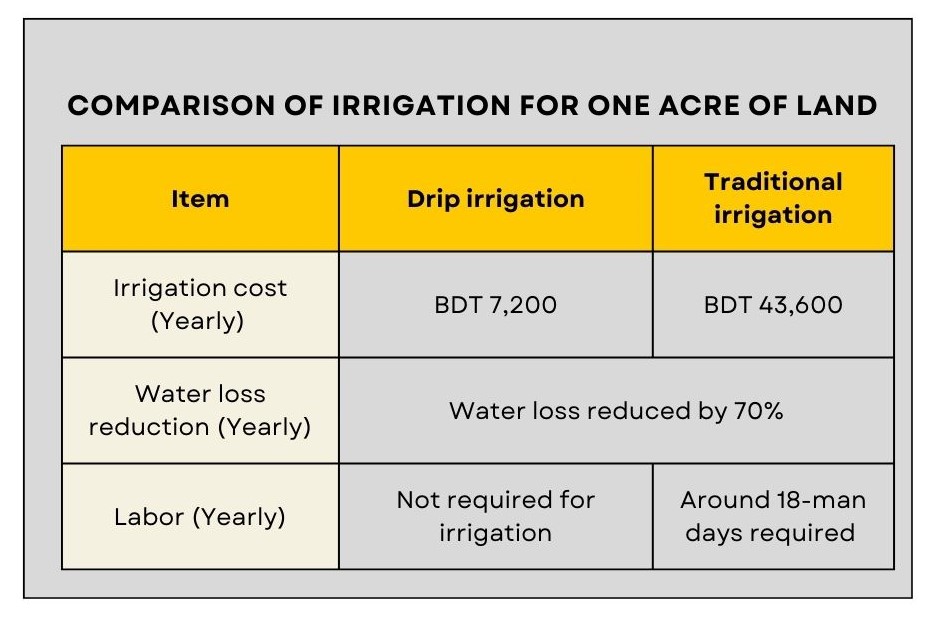

Drip irrigation is widely recognized as the most efficient water and nutrients delivery system for growing crops. By directly targeting the root zone of each plant, this system ensures that the right amount of water and nutrients is provided precisely when it is needed. Consequently, plants can grow optimally, resulting in improved yields and resource utilization.

RMTP has successfully introduced 15 drip irrigation systems across the country. The project has not only equipped farmers with an advanced technology but also fostered sustainable farming practices. By implementing drip irrigation on such a scale, the RMTP project has contributed significantly to water conservation efforts. This technology reduces water wastage by minimizing evaporation and runoff, allowing farmers to make the most of their available water resources.

Expansion of silage production business to ensure livestock cattle feed

Silage is a type of fodder made from green foliage crops which have been preserved by fermentation to the point of acidification. It can be fed to cattle, sheep, and other such ruminants (cud-chewing animals). Making silage is an important way for farmers to feed cows and sheep during times when pasture isn’t favorable, such as the dry season.

RMTP established 70 demonstrations on silage production and provided entrepreneurs with the support of machinery purchase, market linkage and market promotion, both offline and online. Also, contract farming agreement was made between maize/grass growers and silage producers for the consistent supply of maize/grass to the silage factory. This initiative has led to a monthly production of 3,500 tonnes of silage. Additionally, 12,226 farmers are supplying maize/grass to the silage producers, while 33,757 farmers are purchasing the raw materials from them. This initiative has significantly enhanced the efficiency, productivity, and sales of silage producers. Moreover, it has resulted in a 25% increase of income for entrepreneurs and has created employment opportunities.

Sprinkler irrigation revolutionises fruit farming in Tangail

Humayun Kabir from Tangail’s Ghatail upazila runs a 51-acre agricultural farm with pineapple and G-9 bananas cultivated on several acres. Inspired by a local farmer’s use of modern sprinkler technology, he installed it on his farm recently for Tk1.20 lakh.

“Sprinkler irrigation has clear benefits compared to traditional methods. The installation cost will be offset by the system’s lower electricity consumption and improved yields,” he told.

By adopting sprinkler irrigation, Tangail’s fruit farmers like Humayun are revolutionising the cultivation of dragon fruit, pineapples, and bananas.

Farmers and agriculture officials said some are now considering this method for growing other fruits due to its ability to drastically reduce costs, as well as save water and irrigation time.

A sprinkler irrigation device sprays water over crops, mimicking rainfall. It distributes water evenly across fields, helping plants grow while conserving water.

Palli Karma-Sahayak Foundation (PKSF) officials, citing research, said sprinkler or drip irrigation cuts electricity bills by 75%, reduces water wastage by 80%, and lowers labour costs. Irrigation that took four days previously can be done in just 24 hours.

According to farmers, manual irrigation of a one-bigha dragon fruit orchard typically consumes electricity costing Tk7,000-Tk12,000 annually.

In comparison, sprinkler irrigation reduces the cost to Tk4,000-Tk7,000, while drip irrigation lowers it further to Tk 2,000-Tk 3,000.

A drip irrigation device delivers water directly to the roots of plants through a network of tubes and emitters.

Manual irrigation requires around 60 lakh litres of water per bigha. In contrast, according to farmers’ accounts, sprinkler irrigation uses 36 lakh litres, and drip irrigation significantly reduces it to 18 lakh litres.

Society for Social Service (SSS), a private organisation, has introduced this technology to farmers in Tangail.

The Agricultural Extension Department also recognised it as a timely integration. Kabir Hossain, deputy director of Tangail Agricultural Extension Department, told, “This is excellent for commercial gardeners. These methods have long been used in developed countries, and based on our climate, they need to be further integrated into agriculture.”

Alek Sikdar from Tangail’s Ghatail upazila cultivated dragon fruits on 13 acres of land, benefiting greatly from sprinkler technology. He said, “This irrigation method keeps the plants and fruits refreshed. There is no doubt the sprinkler system introduced by SSS is a farmer-friendly technology.”

Abdul Hamid Bhuiyan, executive director of the SSS, said, “Tangail is a major hub for fruit production. We aim to foster the growth of improved, safe crops using modern agricultural systems that conserve water and reduce costs.”

According to the district Agricultural Extension Department, around 19,000 hectares of land in Tangail are used to cultivate fruits like mango, jackfruit, and pineapple. Groundwater is also required for these crops. With many farmers in Madhupur and Ghatail upazilas now adopting water-efficient modern irrigation systems, groundwater will be conserved to some extent.

Farmers said previously they used pipes to water the farmland, but this method didn’t effectively reach the tree leaves.

“With the installation of the sprinklers, all the plants in the garden receive even watering. This has lowered costs and increased yield. In the future, I plan to use the sprinkler system for irrigating other crops as well,” said Md Abdur Rashid from Ghatail.

Agricultural scientists said adverse weather conditions are reducing fruit nutrition and flavour. However, if plants receive water through a sprinkler or a drip irrigation system, along with necessary nutrients, the fruit will be both nutritious and tasty.

In response, a sub-project is being carried out under the Rural Microenterprise Transformation Project (RMTP) to extend and market high-value fruit varieties.

Funded by the International Fund for Agricultural Development, PKSF, and Denmark’s Danida, the project aims to improve incomes by providing quality services, materials, technology, and market access, thereby boosting productivity.

PKSF Managing Director Nomita Halder told TBS, “This project is enhancing the income of ordinary people by offering quality services, ensuring market linkages for products, and increasing productivity.”

The initiative is active in 12 districts, including Tangail, Naogaon, Dinajpur, Khagrachari, Chattogram, and Mymensingh, with at least 58,000 farmers adopting modern technology.

Mozzarella cheese woman of Thakurgoan who works wonders

Cheese production thrives in colder climates making Thakurgaon an ideal location

Life threw an unexpected curveball at Nagina Najnin Banu in 2010. That year, she had to leave her comfortable job and take the business of cheese-making her father had pioneered in Thakurgaon.

In its first year, Najnin’s Eminent Agro Industries Limited yielded Tk9 lakh in revenue mostly from making mozzarella cheese, the special cheese used in premium pizzas. Mozzarella is a semi-soft non-aged cheese from southern Italy. It is prepared with cow milk or buffalo milk, of mild flavour, slightly sweet in taste and stretchy in texture.

Najnin’s father Humayun Reza died in 2017, but she was fortunate that her father had started off a successful cheese production industry in Thakurgaon. And not just Najnin, many others, including women, have since become successful cheese producers in the district. There are 33 cheese factories in this northern district that are mostly agrarian – seven of them operated by women entrepreneurs.

Najnin proudly mentions her company has received the ISO certification – a recognition by an international standard setting organisation adding credibility to a product or service that meets the customer expectations. She recalls how lucky she was to have attracted skilled workers when she started the factory, as many others were closing down in Thakurgaon.

Initially, her factory required 1,500 litres of milk daily and began supplying 500kg of mozzarella cheese per month to a local pizza shop. Later, she secured a deal with a foreign company, which now demands 6,000kg of mozzarella cheese every month, shipping it all the way to Michigan, USA. Najnin also supplies cheese to Pizza Inn with dedicated marketing offices in Dhaka.

Reflecting on their cheese production, she says there is a growing demand for mozzarella, cheddar, and feta cheese, especially in recent years, despite fluctuations due to the pandemic. With upgraded technology, her factory can now process 22 tonnes of milk daily.

Najnin borrowed Tk25 lakh from her mother to start. Her capital has since grown to over Tk60 lakh. The factory sits on a five-decimal parcel of land and she has ambitious plans for further expansion to 42 decimals of land for large-scale production in the near future.

How Thakurgaon became a cheese hub

Humayun Reza, Najnin’s father, worked for an NGO in the 1980s, assisting dairy farmers in Thakurgaon. Seeing that farmers were not receiving fair prices for their milk, he hit on the idea of processing milk into cheese. In 1988, he set up his own NGO called Humanitarian Agency for Development Services, HADS for short, in Thakurgaon, primarily focusing on agriculture, including cattle rearing. But Reza remained committed to his cheese-making vision.

He brought two consultants from Denmark to teach locals how to make cheese. With their assistance, the first mozzarella cheese formula suitable for Bangladeshi climate was developed between 1996 and 1998. After publishing an ad on his locally made cheese, he sold 50kg of mozzarella cheese for the first time under the HADS banner at Sonargaon Hotel in Dhaka. This marked the beginning of cheese production in Thakurgaon, and soon, businesses like Westin and Radisson began sourcing cheese from the region.

His time with international NGOs helped Reza gain access to top hotel owners across the country and he had the opportunity to supply his HADS brand mozzarella and other varieties of cheese to various renowned venues including Canadian Club and British Club. When Reza found it difficult to get loans for his business, as an NGO, Reza established Eminent Agro Limited in 2003. Support from the Canadian ambassador and expertise from an American allowed for further development of cheese technology, and it improved the cheese’s quality. Later, a foreign experts arrived to train local women in cheese production. As a result, more people took up cheese-making and the business expanded across the district.

Currently, seven cheese makers facilities in the area have acquired ISO certification with another 13 in progress. Producers say 350 workers are directly engaged in cheese production and 90% of them are women. The district now produces over 4,200kg of cheese daily, along with 250kg of ghee and 2,500kg of whey.

What makes Thakurgaon cheese so good

Cheese production thrives in colder climates, making Thakurgaon, a northern district closer to the Himalayas an ideal location. Cheese makers there focus on quality and think the milk sourced from farmers is the reason for high quality cheese. Workers in all the cheese factories in Thakurgaon wear clean white clothes. The factory floors are maintained clean at all times. Entry is restricted to workers only. The cheese is stored in a deep freezer until it is ready for sale.

Long time worker Beauty Akter at Eminent Agro praises the excellent working environment at the factory. She has to clean her hands after making cheese and the factory area is regularly sprayed with vinegar. Beauty says that spending most of her day in a clean environment has also impressed her family who now also keep the home clean.

Nurul Haque, deputy general manager of Thakurgaon Bangladesh Small and Cottage Industries Corporation, says the cheese industry in the district is growing steadily. Last year there were 26 factories in the district and now there are 33.

“We are providing loans from the government to four institutions. Others have applied for loans. We are working on their development. However, the role of local and foreign development organisations is more in this industrial development,” he added.

Masuma gains fame

Masuma Khanam, a housewife from Nischintapur area of Thakurgaon, has become one of the district’s successful cheese entrepreneurs.

When her husband fell ill in 1982 and could no longer work, Masuma moved to Thakurgaon town with their children. Over the years, she ventured into various businesses with her husband, and in 2012, following her eldest son’s suggestion, she established a cheese factory in a closed-down facility in Nischintapur.

Masuma’s factory started with just 27 litres of milk but now processes around 2,500 litres of milk daily, catering to increasing demand in Dhaka. The factory generates an income of Tk1.80 lakh per month, employing 13 women and two men.

Encouraged by her success, Masuma’s children have also entered the cheese-making business, setting up factories in Pabna, Bogura, and Thakurgaon, with ISO certification and diversified product lines.

Masuma, who owns multiple plots in Thakurgaon town, is passionate about empowering women in North Bengal and aims to continue working with them.

Her dedication was recognised in 2017 when she received the “Best Small Entrepreneur” award from the Citi Foundation. Additionally, her ISO-certified organisation has received grants from both government and private sectors.

From worker to owner

Rashida Khanam, the owner of Mumtaz Food, is on a remarkable journey from being a worker in a cheese factory to becoming an entrepreneur herself.

She recalls, “I was just an ordinary housewife struggling to make ends meet for my two children. In 2015, I was having a hard time with money and I decided to learn the trade and started my own factory at home. Now, with the help of eight to ten women workers, I run my factory.”

Despite her challenges, Rashida is determined to provide for her family. Her husband, now overseeing the business as a contractor, supports her efforts.

Additionally, Rashida has expanded her business by venturing into ice cream production, ensuring no wastage of milk. She reflects proudly, “I can now use all parts of the milk productively.”

Chandana Rani's goat milk cheese

In 2017, following her husband’s advice, Chandana Rani established a goat farm in Dholarhat, Thakurgaon Sadar. Initially, she was simply caring for goats, but after attending private training sessions, she recognised the potential of goat milk and its market value.

With a herd of 103 goats, she now produces 10 to 15 litres of milk per day, which she supplies to Cheese Land, a cheese production factory. The market price of goat milk is now Tk100 per kg. Meanwhile, Jahangir Alam, the owner of Cheese Land, transitioned from his previous role as a marketing officer at Eminent Agro to owning his cheese factory.

Initially starting with five workers in 2013, he now employs 22 workers. Jahangir says effective marketing is important in the cheese industry. “Despite producing high-quality mozzarella cheese, success hinges on strong marketing efforts targeting big hotels and restaurants.”

Milk supply

As many as 3,865 dairy farmers supply milk to the cheese factories in Thakurgaon. There are also 70 milkmen in the area who supply milk directly to factories from farmers. Dairy farmer Mahfuza says, “Earlier we used to breed local cows. We used to feed the cows as we always used to do. But now I don’t do anything without the doctor’s advice. Due to this, safe milk is available. We now supply milk to cheese factories through milkmen.”

Another farmer, Gulshan Ara takes care of three cows at home. She says, “We are doing well because of the demand for milk in the cheese factory. No need to go to the market to sell milk. There is no more worry about the education of my children.”

There are milk collection points in the cow farming areas of the district. From there the milkmen collect milk at certain times. A profit of Tk1 is paid per kg of milk delivered to the cheese factory. Milkman Kalipad Sarkar says, “We have benefited a lot due to the cheese factories in the district. Now there is no tension about selling milk. No matter the storm, the rain, our income does not suffer. Our safe income is here.”

Meanwhile, a factory called Pure Agro has been established in Thakurgaon to produce maize silage, recommended as an excellent feed option.

Golam Sarwar Robin, the company’s owner, says their company produced 12,000 tonnes of silage last year, which is purchased by farmers across the country. Silage is highly beneficial for cows and can be stored for several years.

Abul Kalam Azad, the district’s livestock officer, says the district has two lakh cows spurred by the huge demand for milk. This demand has surged due to the increasing number of cheese factories, resulting in fair prices for farmers and attracting new entrepreneurs to the industry.

Potential of Thakurgaon cheese

Reliable information regarding the cheese industry was not available in any government office in the district. However, the Eco-Social Development Organization (ESDO) has been actively supporting cheese industry entrepreneurs in Thakurgaon by providing various assistance, including micro-credit and conducting research.

Md Shahid Uz Zaman, executive director of ESDO, says the demand for milk in the district is at least 50 tonnes per day. The daily demand for mozzarella cheese in the country is 5,000kg to 6,000kg, with Thakurgaon contributing to 75% of the production. Cheese is sold at Tk500 to Tk600 per kg, resulting in annual cheese production in the district exceeding Tk90.72 crore. Samples have already been sent to South Korea for export, and if accepted, Thakurgaon could potentially export 4,000 kg of cheese to South Korea monthly, he adds.

Besides, through initiatives like the PKSF’s (Palli Karma-Sahayak Foundation) “Rural Microenterprise Transformation Project”, farmers have been trained to produce pure milk, resulting in high-quality cheese.

Donor organisations such as IFAD, the Danish Government, and the PKSF are providing financial and technical support to farmers through ESDO.

Deputy Managing Director of PKSF, Dr Akond Md Rafiqul Islam, says the project aims to enhance the value chain of agricultural products using technology, with ongoing activities in cheese and other sectors, benefiting stakeholders and aiming for continued success in the future.

https://www.tbsnews.net/economy/industry/mozzarella-cheese-women-thakurgaon-who-work-wonders-805490

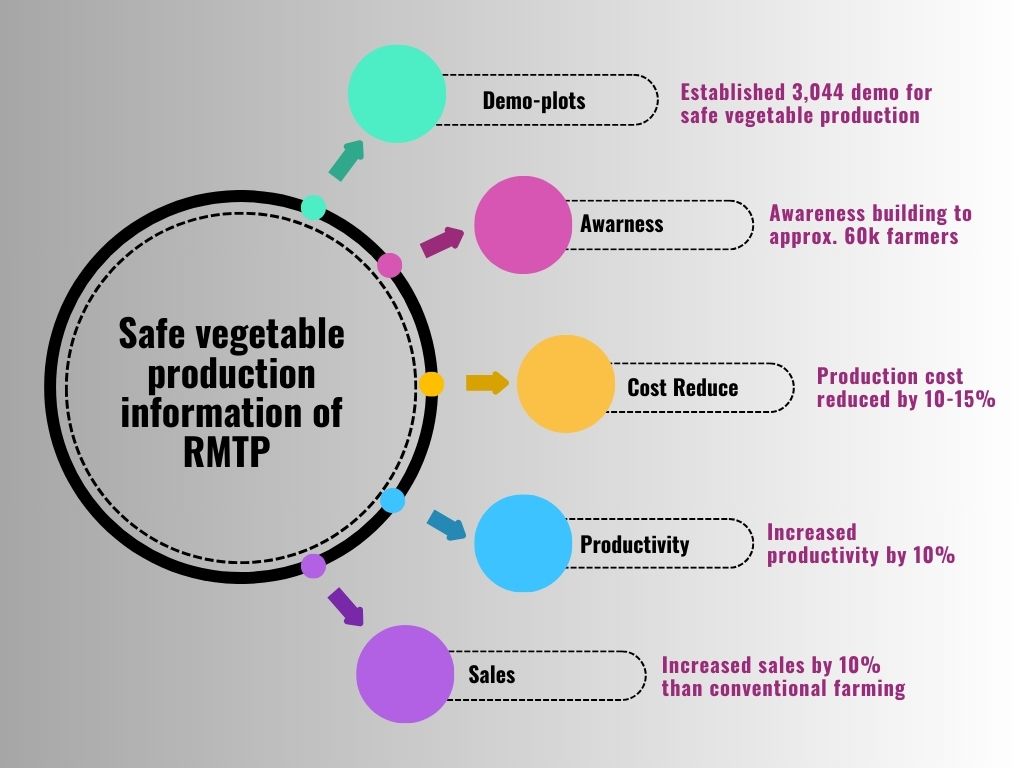

RMTP supports farmers yield pesticide-free vegetables

RMTP has completed an extensive pesticide residual test involving 12 different vegetable samples. The primary objective of this test was to assess the presence of potentially harmful pesticide residues in the produce under examination. These tests encompassed vegetables cultivated by the project-supported farmers as well as those collected from farmers excluding of the project.

The results of this investigation have generated optimism, as none of the samples from the project-supported farmers tested positive for any harmful pesticide residues. However, harmful pesticide residues were detected from the vegetables outside the project. The positive aspect of this development is that farmers participating in the safe vegetable production initiative are now higher prices for their crops compared to the past.

G-9 Banana production expansion in Bangladesh

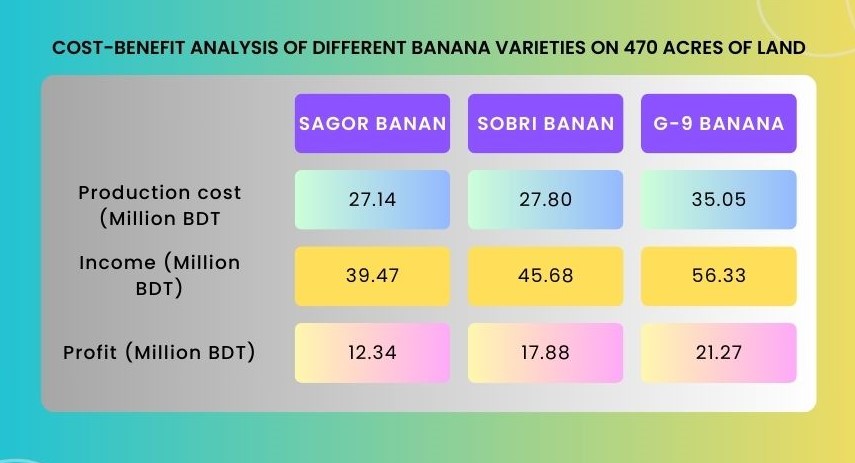

RMTP project successfully expanded G-9 banana production by distributing 47,000 G-9 banana seedlings among 235 farmers in Tangail and Mymensingh districts, which is producing on 470 acres of land. In addition to the seedlings, the project has provided comprehensive training, technical knowledge, and safe production methods for cultivating bananas, as well as guidance on effective marketing strategies. Furthermore, the project has established market linkages with potential export organizations, allowing the bananas to be sold not only in local markets but also in the international markets. The farmers who have adopted G-9 banana cultivation have experienced significant profits, doubling their earnings compared to other banana varieties. This success has generated considerable interest among other farmers who now wish to cultivate G-9 bananas. Recognizing this demand, the project has facilitated connections between enthusiastic farmers and G-9 banana seedling suppliers, fostering a sustainable supply chain for future expansion.